Nasza oferta

Pobierz katalogproduktów

EPP – Rubber, modular FLIP - FLAP screens

EPP rubber screens are aliasing with reliability and long life. Nowadays rubber, modular screens are the best choice in sense of material classification according to the thickness and enrichment technology. Although rubber screens are more expensive than steel screens, their use in classification of minerals and enrichment technology spread rapidly.

Our screens have been working in an ore and coal enrichment plant kombinatach koksochemicznych, metalurgicznych, coal mines since 15 years. They were introduced on the polish market in 2004. To meet the increasing demand of screens we only use the highest quality rubber mix for their production. Depending on application and work condition we use rubber mix with hardness between 35 to 85 ° Shore'A.

Benefits of EPP

1. Occuracy of sieving due to precise of meshes,

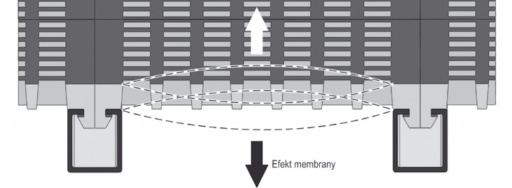

2. Self – clearing ability - występuje efekt membrany due to own vibration of screen and conic shape of meshes.

3. Highly wear resistant by using the highest quality of rubber mix,

4. Noise reduction due to attenuation of sound waves by rubber,

5. Economy by replacing only individual and used sieving modules,

6. Compatibility of modules – we offer a full range of meshes,

8. Easy to install due to small sizes of screens.

Assembly and disassembly of rubber, modular screens do not required any special skills or training. We use a hammer for assembling and a screwdriver for disassembling. To push the rubber screen in a construction you need only few strokes. To disassembly the screen, you need to use a screwdriver and pull one of last part of the screen. Further pulling causes release a screen’s hook from a construction.

Classyfication on screens

High and dynamic activity cause reducing obstruction meshes of screens ( self – cleaning) by grains. It also reduces clamping of material. Due to them we can get efficiency over 90%.

Benefit of the screens:

- highly wear resistant,

- resistance of repeated impacts,

- different kind and sizes of materials

Vitality of ore materials after processing lasts 12 months. Vitality of softer materials (e.g. coal, etc.) lasts up to 3 years.

EPP rubber screens don’t corrode and reduce noise level during processing.

Dewatering and desludging – ( Only on screens)

Dewatering and drying after dehydration are one of the most energy efficient operation in a technology process. Modular, rubber screens EPP allow to obtain a final product of humidity of 10-15% in a dewatering process, for a grain size over 2 mm. Humidity of 16-21% we can achieve for grains size below 2 mm. Dynamic activity of screens allows to increase specific gravity of load on water 2 to 3 times. A advantage of the screens is to self cleaning ( meshes are not clogged). They can be used in wet machines with flat and sloping surface. They also can be used for vibrating, drum and stationery screens.

We recommend to use our screens to achieve better results of dewatering materials in your enterprise.

Offsetting – on pulsators

The most popular method of enrichment coal is gravity separation. It means hydro dynamic offsetting in a aqueous environment. Modular, rubber screens EPP give possibility to achieve better efficiency of enrichment and increase machines productivity. It is indicated by experience in pulsator operating, theoretical and experimental research of offsetting process. We recommend to use our screens to avoid clogging of meshes, which reduce the time of service a pulsator.

They are deliver and install on machines without any changes in construction of a screen.

powrótdo góry

powrótdo góry